I have researched hundreds of topic over the past few days so that I could make the most educated decision on which alternate solution would perform the best, utilize materials the best, and be the most cost efficient. I have decided to go with Alternate Solution #3. Although my brainstorming and alternate solution was very broadly described when I was first pondering the possible idea of it, it seems that it is much more versatile and adaptable than expected.

Here are some things that I researched and how they best relate to my selection:

1) Analog versus Serial data

- Serial data is very valuable and practical in the real world. Everything from lights to displays to monitors and even how your car runs is based off of serial data. There had to be a reason why it was so universally used, and I couldn’t be blind or ignorant towards it. Serial data is sending out values that a microcontroller can transmit and receive. It takes data and sends it out almost instantaneously with sets of binary digits in 8 bits per byte. This is very interesting because instead of using 6 wires to control the motors like in Alternate Solution 1 and 2, I can use 2 wires: Transmission and Receive, which will allow a lighter, more flexible and versatile tether. On top of this, it opens up many doors to me as to how much data I can manipulate underwater such as sensors and gauges.

Above: Displaying how 8 bits is equivalent to 1 byte. Showing how serial data is emitted in series of consecutive 1s and 0s (binary notation). Photo credit to http://www.tldp.org/

2) Pulse Width Modulation (PWM)

- Pulse with Modulation was a very hard topic for me to grasp at first. The original concept started back with electricity and dimming lights using an analog dial. There was a coil of wire wrapped around in a circular fashion. The electricity came in, and when the dial was all the way at the end, there was not much that the electricity had to travel to get to the emission source, hence little resistance, and brilliance from the source. As the user rotates the dial counter the direction of the start of the coil, a needle would go further and further away from the electric source with increasing resistance. The electric would have travel through more of the coil, and lose amperage through the wire before it got to the lights causing it to dim. This method may be used to control motor speed to this date, but it is very inefficient. There are no speed increments, or steady values, and there is a lot of room for error. In this day in age, we are able to change this analog method to a serial-based transmission. The microcontroller tells a Pulse Width Modulation (PWM) Unit to send out the electric in pulses. This is equivalent to rapidly turning a switch on and off. The unit will work at the nanosecond level or better to activate the switch on and off repeatedly. If the PWM unit keeps the switch on for a second, then off for a second, and then on for a second, we have a pattern known as a 50% - 50% pattern. This means that the motor is only drawing the amperage that it needs to operate 50% of the time, which means that it is operating at ½ of its peak speed. This is essentially a very efficient motor speed controller that I can program to any button or analog stick on my PlayStation controller which allows a lot of maneuverability and versatility in the ROV project.

Above: Showing the equivalent of a duty cycle and its relationship to a period cycle. This is the ratio that I was establishing earlier visually. Photo Credit to: National Instruments Inc. (http://www.zone.ni.com/)

Above: Showing the difference in changing length of the Duty Cycle to demonstrate how percentage of total motor speed can be calculated. (Photo Credit to: National Instruments, http://www.zone.ni.com/)

3) PlayStation 2 Pins

- Using a Hewlett Packard 54602B Oscilloscope, the data for the PlayStation 2 Dualshock Controller pins have been discovered. Using 5 Volt logic, which is the foundation on which the controller runs, the different wave transmitted onto the screen show the values of each one of the wires. The most significant wires detected are wires one, two, six, and seven. In consecutive order, one is data, two is command, six is attention, and seven is clock. These 4 wires are required for the microcontroller to communicate effectively and efficiently and manipulate it. In addition wire four is the common ground and wire five is 5 volt positive voltage into the controller. Wire three is optional for use of the motor rumble (only has to be positive 9-12V) and wires 8 and 9 are useless for ROV purposes. Now knowing the background and what we are looking to accomplish, my personal goal is to figure out how to power such a device and a microcontroller from the energy given to us in the specifications of the project.

Above: Using an Oscilloscope mentioned in the paragraph to determine the values and the data required to operate the PlayStation 2 controller. Photo Credit: Bill Porter at http://www.billporter.info/

Above: The overall pin diagram from the plug to the wires and a short explanation as to what every pin does on the PlayStation 2 DualShock Controller.

4) Step Up / Step Down / MOSFETs

- There are many ways to convert voltage by either multiplying amperage downward or by dividing amperage upward. As learned in Marine Physics, Voltage is equivalent to current multiplied by resistance. This mathematical principal proves how electricity behaves in circuits, and we have to abide by these guidelines for our research purposes. Most streets in today’s infrastructure have a humming green box that is known as a transformer. Voltage is stepped up from the power company using a transformer and transferred at a high voltage / energy level. They use high voltage because high amperage or current would be a lot of flow and frictional heat would be emitted and would cause more wear and tear on the infrastructure. These transformers step up or step down voltage by creating a ratio of loops around a circular magnet. This large magnet is able to turn 12V with 10 coils into 6V with 5 coils on the other end. This principle is very efficient and proves very useful in modern society, but for the purposes of this project, we do not need something on that large of a scale.

Credit to Serway and Beichner for diagram from Physics for Scientists and Engineers Fifth Edition Volume 1. Diagram accurately portrays step-down transformers used in most homes.

- This is where we incorporate MOSFETs. It’s a very difficult acronym to pronounce and it’s very intimidating in long-written form. A Metal Oxide Semiconductor Field Effect Transistor(MOSFET) is a linear step down or step up converter. They are capable of withdrawing a voltage up to 35V and stepping it down to whatever you would like. The most common configurations are 78xx integrated circuits. For example, in this project, I would have to use a 7805 MOSFET because this takes any voltage supplied to us, in our case 12V, and steps it down to the last 2 digits of the numerical value, 05 Volts. This will supply up to 1 Ampere of electricity to the PlayStation 2 DualShock Controller and the Arduino Microcontroller. It is known in modern day Physics that when an electron is stepped down from 12 Volts to 5 Volts, there is energy loss given off in the form of heat. Although this is not the most efficient way to step it down, it is the easiest and most space saving component that would satisfy our needs. To protect the MOSFET from overheating and shorting out at any point during this project, a Heat Sink has to be added to the metallic backing with thermal compound.

Above: Primary Example of a Metal Oxide Semiconductor Field Effect Transistor that steps-down voltage on the low current / amperage level for small projects. This is very efficient and satisfies our needs with not much expense or difficulty. (Vishay.com/MOSFETs)

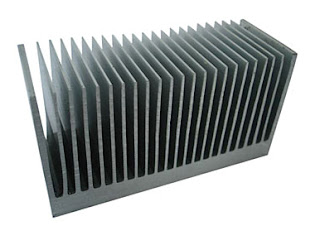

5) Heat Sinks / Thermal Compound

- Heat Sinks are devices made out of metal that are designed very creatively to maximize surface area while minimizing volume. This allows heat to be dissipated and to allow maximum air flow to travel between the fins of the heat sink. Thermal compound has to be applied in order to make a nice solid connection because most glues and epoxies will melt and turn into an unusable inefficient state and could fry the component once detached from a MOSFET. Heat Sinks most common application in my opinion would have to be in computers. The processing unit is very hot, and intricate heat sinks are used to dissipate any heat from it and make the computer perform significantly better.

Above: Prime Example of a Heatsink that optimizes surface area and minimally uses volume to increase air flow between the fins to dissipate heat at the fastest rate of change. (Photo Credit: http://www.heatsink-guide.com/)

Between researching all of this material above, I feel that the Arduino Microcontroller and the Playstation 2 Dual Shock Controller would provide us with the most efficient and versatile method of following through with this project.